Samsung Display participates in ‘SID 2017’ exhibition hosted by the world-renowned Society for Display Experts ‘SID (The Society for Information Display)’ to show advanced future display products.

Samsung Display will exhibit advanced display products that have never been revealed before, such as a stretchable display and a non-eyewear 3D OLED at the LA Convention Center in Los Angeles on 23rd (local time).

Samsung Display participates in this SID 2017, and is showing the unrivaled display technology leadership and confidence by showing high-tech products and publishing outstanding papers.

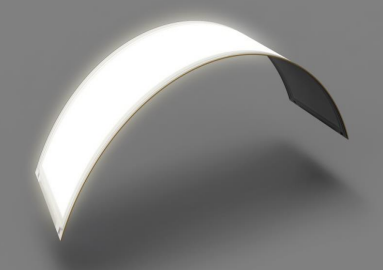

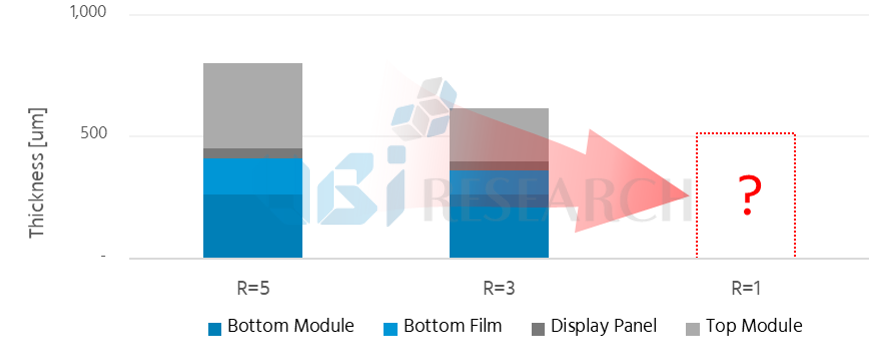

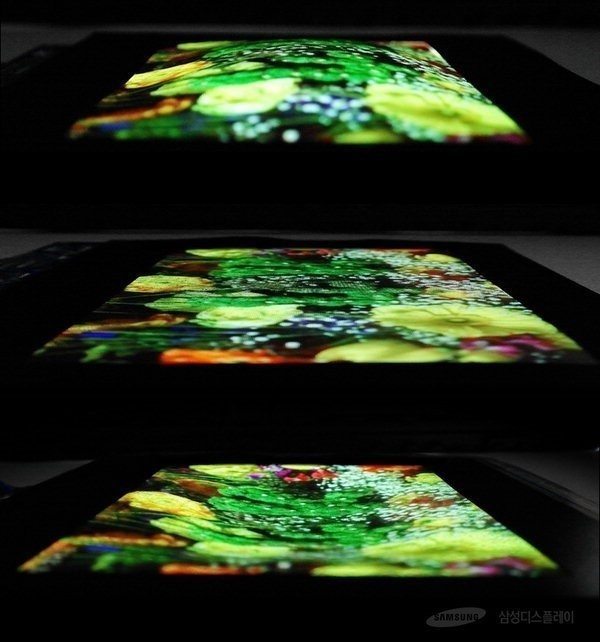

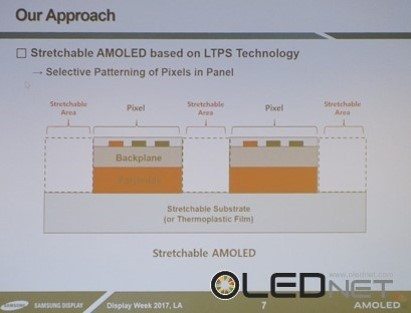

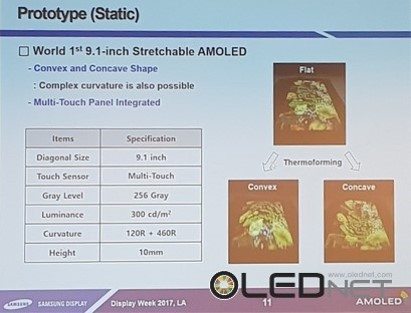

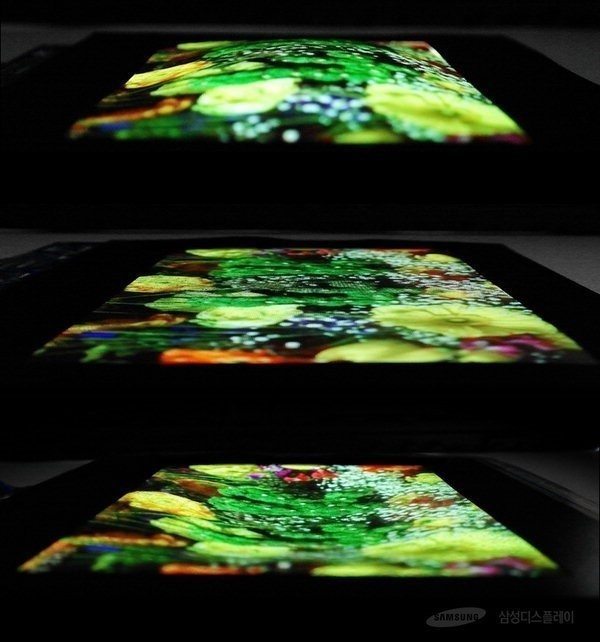

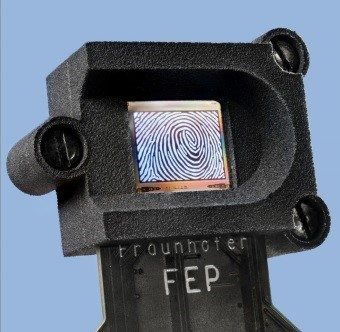

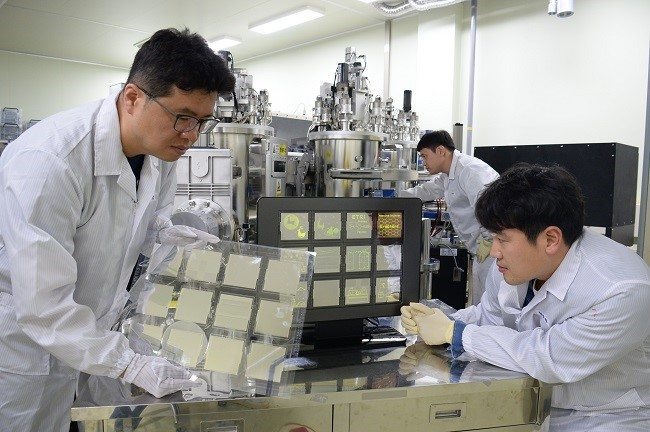

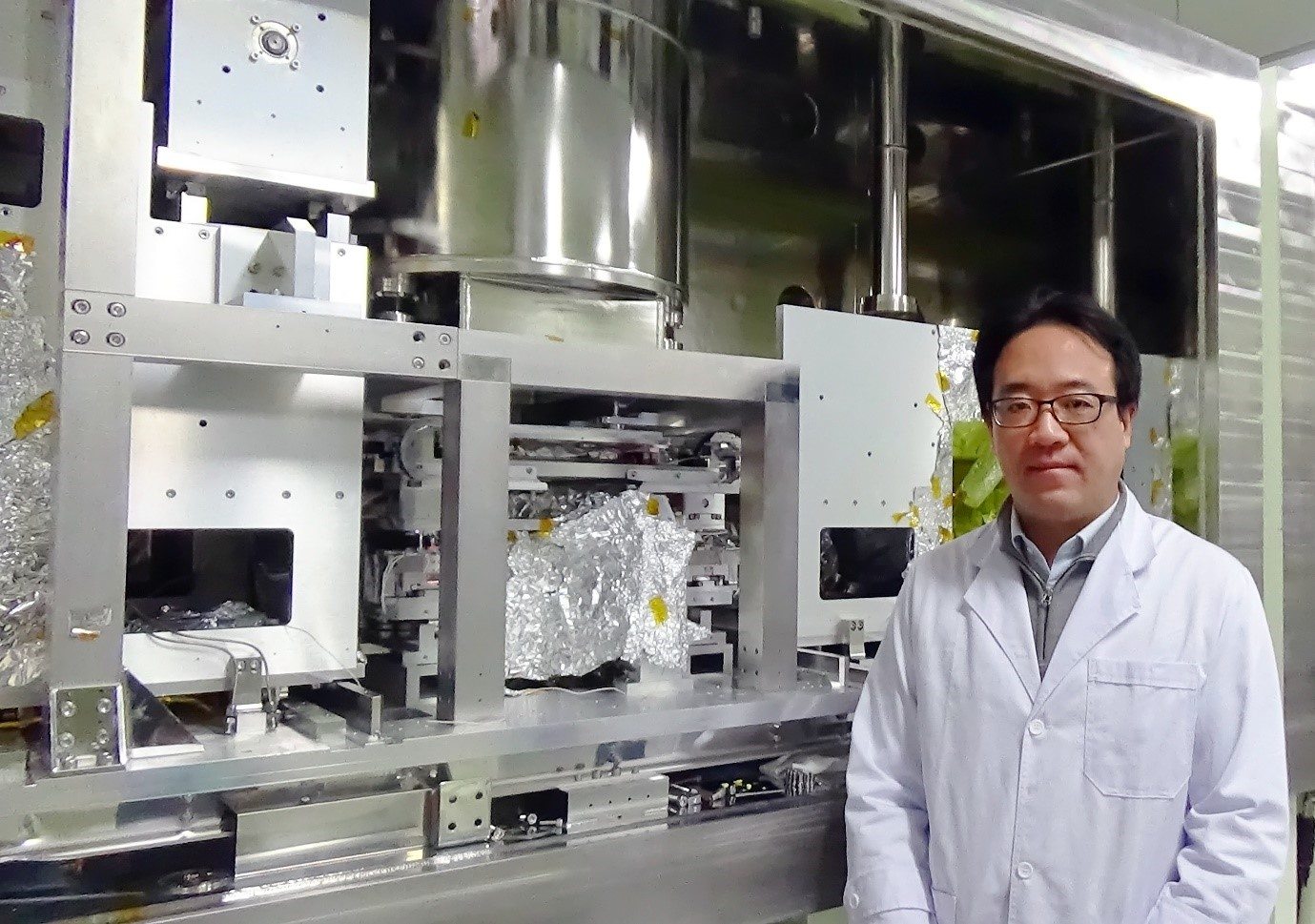

Samsung Display unveiled a 9.1 inch stretchable OLED product with stretching screen. The stretchable display is the next generation display technology that extends the screen flexibly, and it is considered to be the most suitable technology for wearable, Internet (IoT), AI (AI), and car display.

<source : Samsung Display>

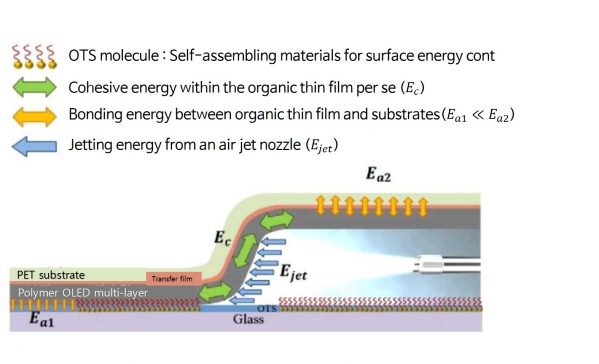

Compared to the existing flexible OLEDs that can be deformed in only one direction, such as bending, folding, or rolling a screen, a stretchable OLED can be deformed in more than two directions. This is a much higher level of implementation difficulty and is often referred to as the end point of flexible display technology in the industry.

The product displayed this time, when the screen is pressed from above, the screen is dented like a rubber balloon, and then returns to its original flat shape. On the contrary, when pressed from below, the screen stretched up and had the elasticity to recover. Samsung Display has developed a high level of stretchable technology that maintains the original picture quality while increasing the screen to a depth of up to 12mm when the display is pressed through steady research and development.

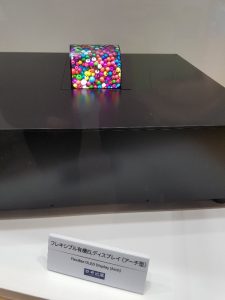

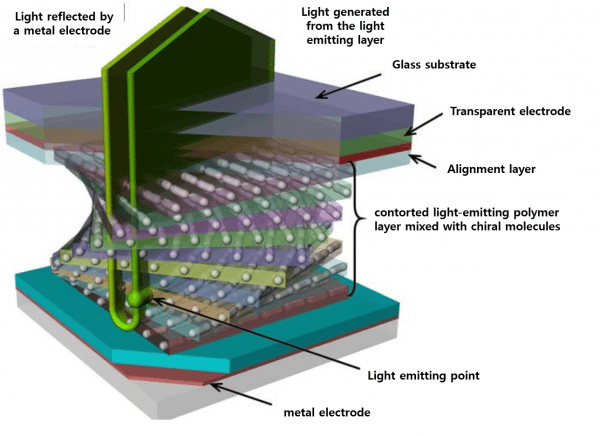

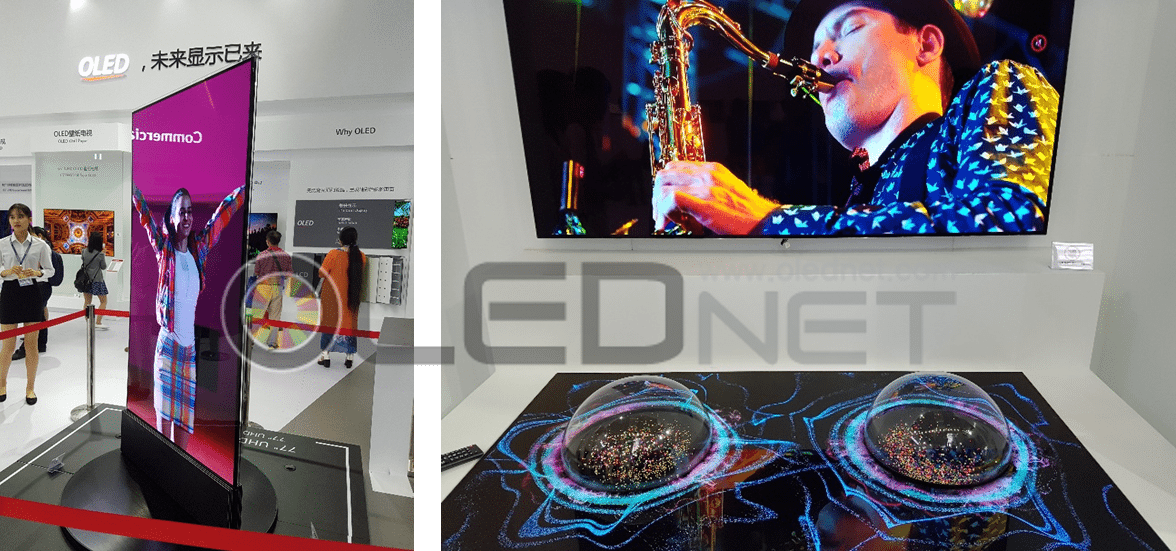

In addition, Samsung Display will exhibit ‘non-eyewear 3D OLED’ products. This 5.09-inch product realizes a real-life image that looks a bit different depending on the viewer’s position on the display, and expresses a more realistic 3-D image.

Especially, due to the contrast ratio close to infinity of OLED, it shows more natural stereoscopic image than LCD product. This technology is expected to be utilized in various fields requiring 3D image technology such as 3D pop-up book, 3D game, VR and etc.

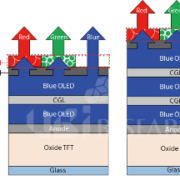

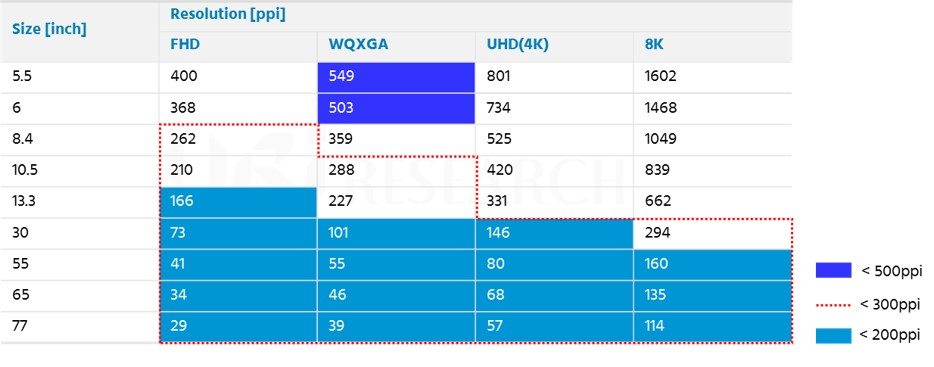

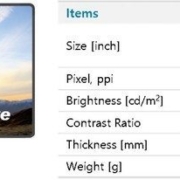

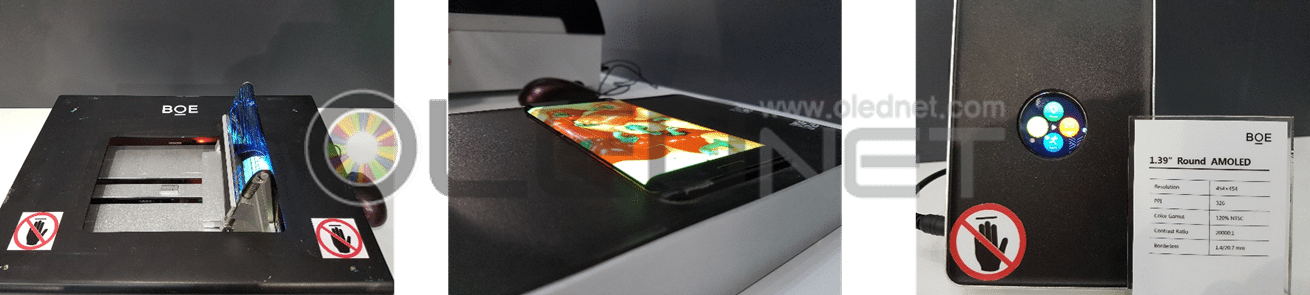

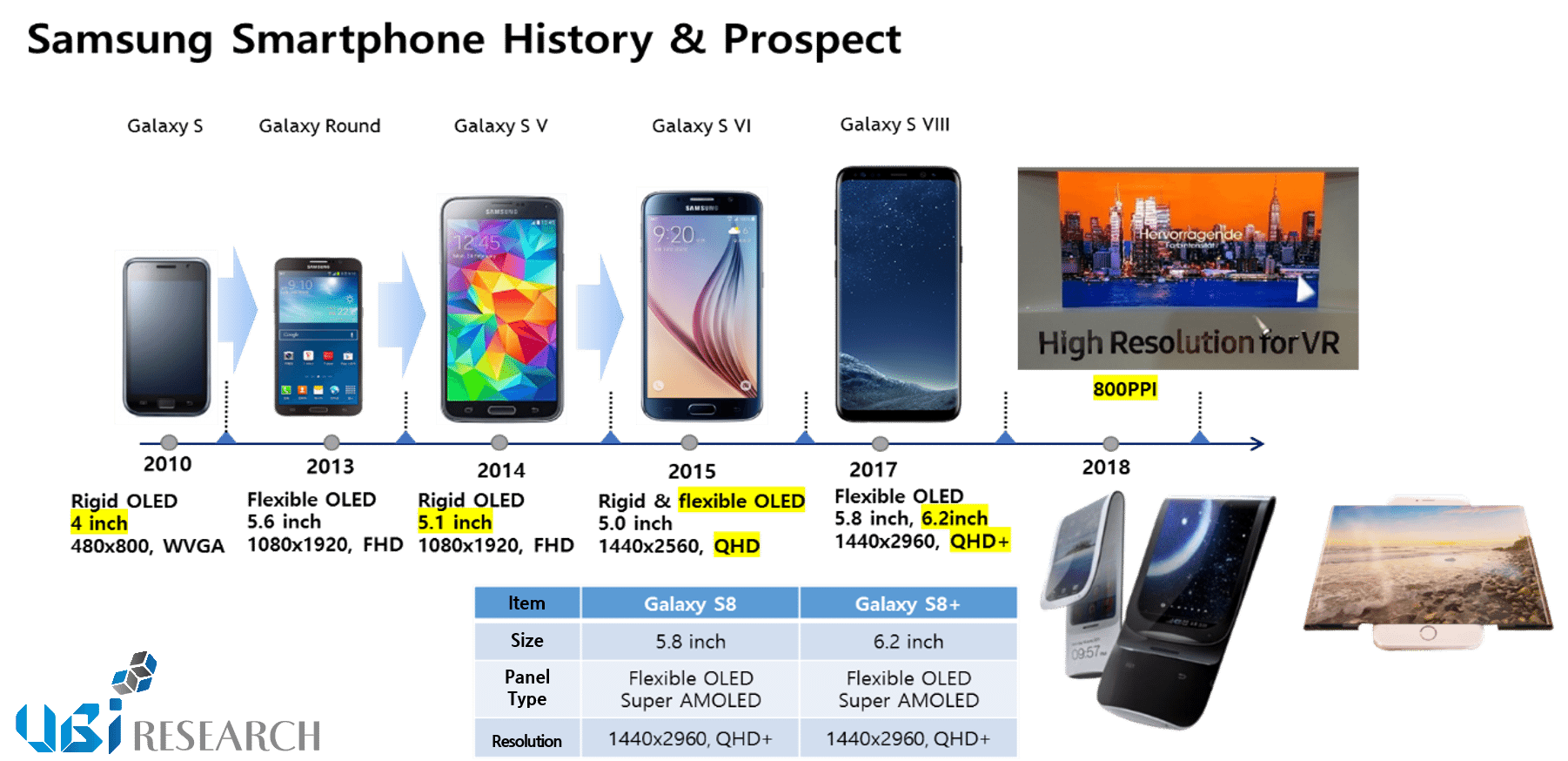

On the other hand, this exhibition will have booths that enable users to experience the OLED technologies of Samsung Display. Including 3.5-inch size, 858ppi optimized for VR devices, 120Hz for wearable and tablet OLED products for smooth picture quality are exhibited.

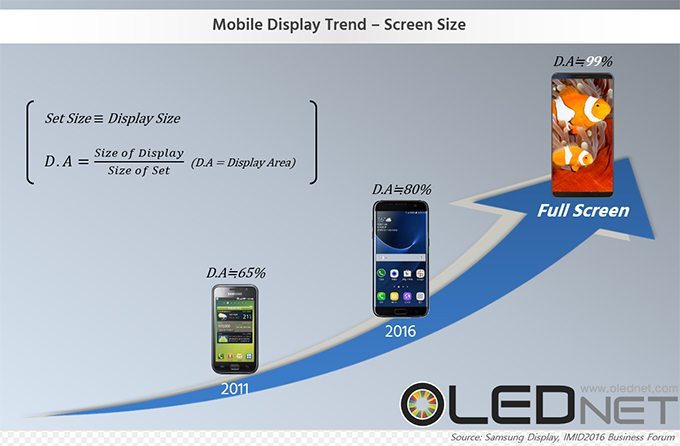

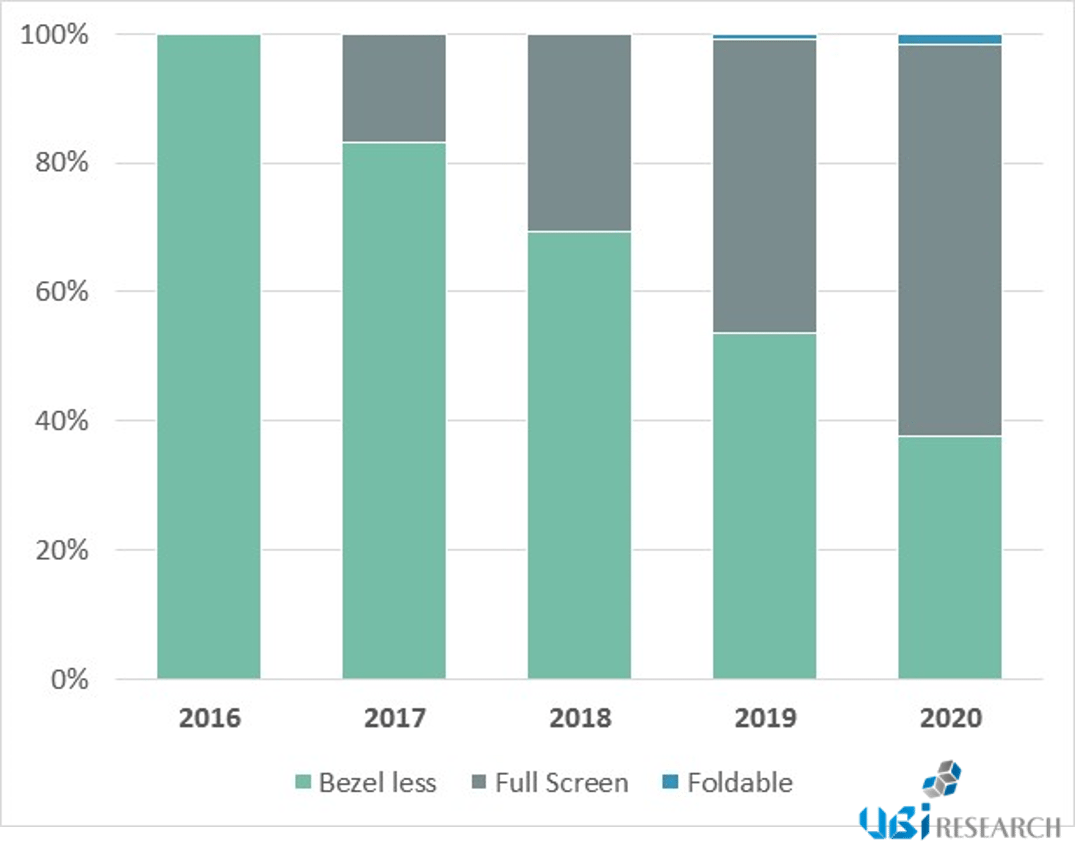

In addition, much improved image quality of OLED, HDR (High Dynamic Range) and low power consumption technology can be confirmed. Samsung Display also offers a ‘Design Innovation’ corner that introduces the development of smartphone display design, a unique flexible OLED technology.

From round OLEDs applied to mobile phones for the first time in the world after the successful production of flexible OLEDs in 2013, to recent full-screen OLEDs with the highest picture quality rating of ‘Excellent A +’ from DisplayMate, an image quality evaluation agency, it is able to show the flexible OLED technology accumulated by Samsung Display at a glance.

In addition, a high-resolution 65-type frameless LCD curved TV that minimizes screen reflections by applying ultra-low reflection POL (polarizer) and achieves 100% color expression power (DCI-P3 standard), 34-inch QHD + (3440X1440) LCD curved monitor with 21: 9 aspect ratio maximizes information transfer efficiency and 27-inch FHD (1920X1080) LCD curved monitor capable of 144 Hz high-speed screen operation are exhibited as a product that embodies innovative technology

Meanwhile, a paper entitled “Extendable Screen with Stretchable OLED Display” of Hong Jong-ho, researcher of Samsung Display Research Institute selected as SID 2017 Distinguished Paper.